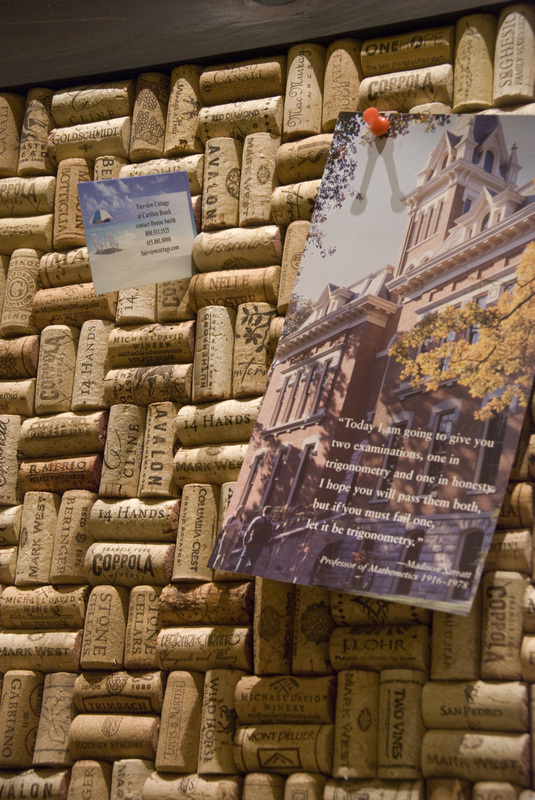

The first order of business was a little online research about wine cork boards. Of the hundreds of photos I saw on Google, I didn't find many that were particularly attractive. Most were very small and impractical looking and the workmanship wasn't there. Some people had cut their corks in half long-ways to double the surface area their corks would cover. Good idea in theory, but I thought this might cause problems when trying to pin things to the board because you might put a pin in a spot that had a limited amount of cork depth. A lot of boards had rows of corks that weren't straight or were cut to fit in a particular space. I knew I didn't want that either. I wanted a BIG, dramatic board that had plenty of space for photos, notes, etc. and doubled as a center piece or work of art. With these thoughts in mind, I got to work!

The cork boxes in the trunk.

The cork boxes in the trunk.  Plywood base. I included a yard stick for reference.

Plywood base. I included a yard stick for reference.  Corks next to a 1"x4"

Corks next to a 1"x4"  Corks next to a 1"x4" with a 1/4" shim underneath.

Corks next to a 1"x4" with a 1/4" shim underneath. This was a frustrating discovery. At the time, I knew I had some boards that were 3/4" deep and that I wanted about a 1/4" of extra depth for the framing boards. So I went to Lowes looking for a true 1"x4" board, which, much to my chagrin, didn't really exist. So after some brainstorming, I bought a 1/4" piece of plywood that was 2'x4' and cut it down to fit the 1"x4" boards I had at home. I also bought some 1-1/4" wood screws.

Zig-zag pattern demonstrated with pencil.

Zig-zag pattern demonstrated with pencil.  1/4" ply planks being glued to the 1"x4"s.

1/4" ply planks being glued to the 1"x4"s.  C-clamp with wood block "padding."

C-clamp with wood block "padding."  Frame done! Just have to screw it down.

Frame done! Just have to screw it down. (It looks warped because of the wide-angle camera lens.)

The boards need sanding...

The boards need sanding...  My orbital sander.

My orbital sander. Another tool that is really handy to have is a square. It's basically a ruler with an attachment used to measure right angles. I used one to get the ends of the boards flush.

Up until this point, the whole project was on the ground.

Up until this point, the whole project was on the ground.  Screws placed in between the clamps.

Screws placed in between the clamps. No need to drill pilot holes for these things. The wood screws went straight in.

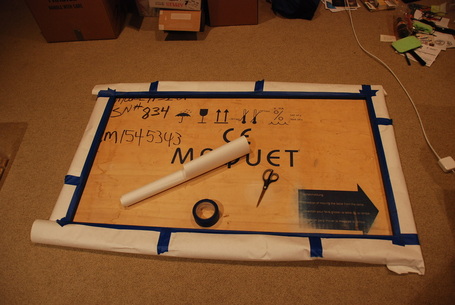

Edges masked off with some painters tape and paper.

Edges masked off with some painters tape and paper. So I masked the border and went back to Lowes to get some dark brown spray paint to cover the base. I also picked up a 1/2-pint can of very dark wood stain for the border to give it a strong contrasting hue in relation to the lighter colored corks. Here's a link to a video about staining a piece of wood. Going back to my original idea, I envisioned a large and dramatic wine cork board. We'll see!

Some rows were indeed a very tight squeeze and sometimes a whole row would pop out under the pressure while I glued down others. This part of the project easily consumed of the majority of the time spent on it.

I suggest making a good Pandora station and finding a huge dose of patience. I had to step away from it many, many times for sanity's sake. The tedious labor of getting 1,116 corks down and glued was certainly worth it though in the end because it all came together to make a beautiful piece.

One final thing that kept me going was that I had decided during the process to give the board to my dear friend Adam and his new wife Lauren as a wedding gift. Thinking of them often gave the little extra push it took to get another row down at 2am on many occasions.

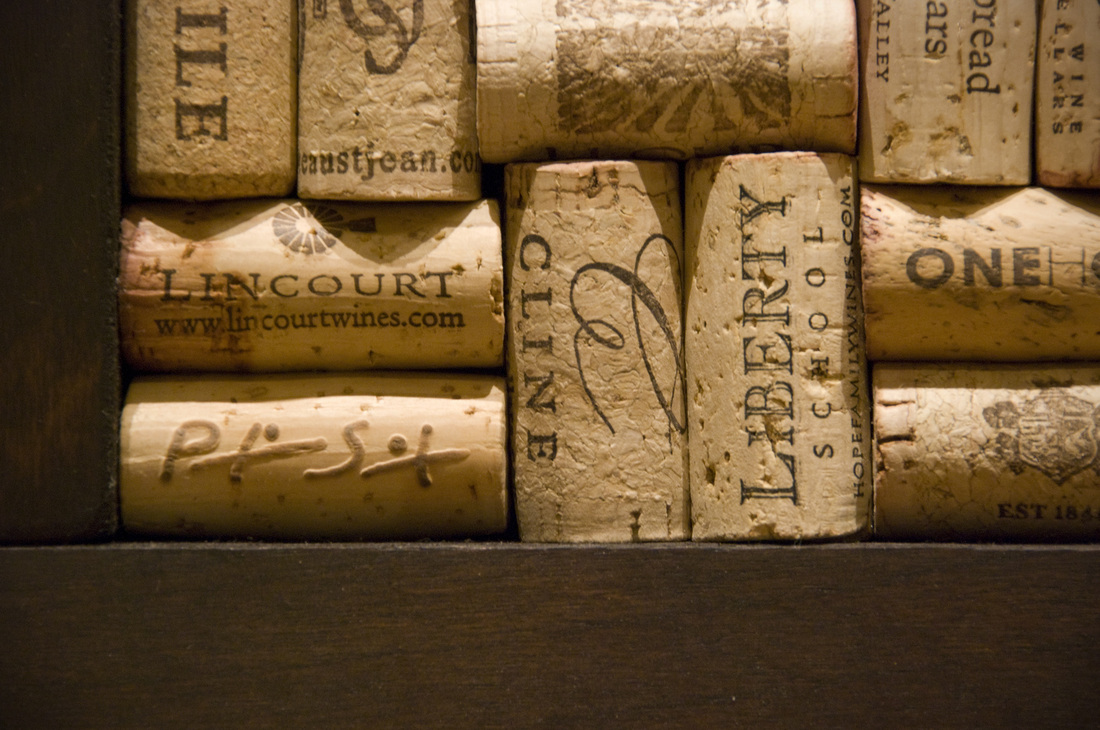

I'm leaving you with some final pics and hidden details of the project. Hope it inspires you to tackle a project of your own! Good luck!

RSS Feed

RSS Feed